“QUALITY IS THE MOST IMPORTANT”, THE ENTERPRISE DEVELOPS BY LEAPS AND BOUNDS

2020 is destined to be a very extraordinary year. At the beginning of the year, the state forced the pause button. At the beginning of February, the government emphasized the resumption of production and production, and on the other hand, it required enterprises to implement the main responsibility for epidemic prevention. Due to the adjustment of national policies, local governments are required to do a good job of infrastructure construction. The orders of enterprises related to water conservancy and municipal administration have skyrocketed. With the strong support of the group, Shanghai Liancheng Group Suzhou Co., Ltd. has made great efforts to grasp the delivery of water conservancy orders and the production and delivery of major projects. The premise of delivery is high quality, and product quality is the foundation of enterprise development.

As one of the largest manufacturing bases of Liancheng Group, Shanghai Liancheng Group Suzhou Co., Ltd. is one of the industry’s largest pump production model demonstration areas. It has the largest processing equipment in the large-scale water pump industry, a 10-meter vertical lathe and the largest performance test in East China station. In 2020, large-diameter water pumps made another breakthrough, 1600QH-50, 4, Q=10M3/S H=9 N=1200 KW. At present, the industry’s highest power high-pressure submersible axial flow pumps are currently being organized and tested.

In 2020, we will successively produce and deliver the multi-stage centrifugal pump SLOW-K250-560*4, Q=900 H=360 N=1600 of the Chengdu Yulong Snow Mountain project, and the project is used on a plateau with an altitude of 5000. The project requires high manufacturing precision of the pump to ensure that the efficiency, vibration and cavitation meet the customer’s requirements. The completion of the production of the Kunming Erhai Project in Yunnan requires the shell to withstand 7.5MPA, SLK250-490*5, Q=0.24m³/S H=365.78 N=1250. Through the Jiangsu Pump Valve Product Quality Supervision and Inspection Center and the component center test bench, high-pressure and full-speed experiments, the efficiency, vibration and cavitation are better than the national standards. The technical requirements of multi-stage open pumps are high, the production is difficult, and there are few manufacturers in the industry, most of which are not specific technical capabilities and manufacturing capabilities. It requires stable and reliable operation, high precision of rotor dynamic balance, and concentricity and coaxiality must be ensured during processing. The two bearing body parts must be processed simultaneously. Suzhou Joint Stock Company fully exerts the team fighting spirit, from technical personnel to technical personnel drawings, process calibration, quality control personnel, workshop production personnel all dispatched troops to ensure product quality in the future, from special machine barrels and tools, including process protection to find ways to ensure product quality. Assemble, test and produce, and assist in perfecting product manufacturing throughout the process.

Enterprise management is a bit simpler, that is, to correct errors, so that those who do wrong things can understand what is wrong and improve it after correction. There is a famous saying in the field of quality control, that is, “quality starts with education and ends with education”. People’s work attitude and methods determine the main factors of product and service quality. High-quality work attitudes and methods are not innate, but continuous training. The scientific management system, standards and methods are the core of enterprise management. The production factors of the factory include people (workers and management personnel), machines (equipment, tools, sites, station equipment), materials (raw materials), and methods (processing, Testing methods), environment (environment), letter (information), etc. to carry out reasonable and effective planning, organization, and coordination to achieve high-quality, efficient production.

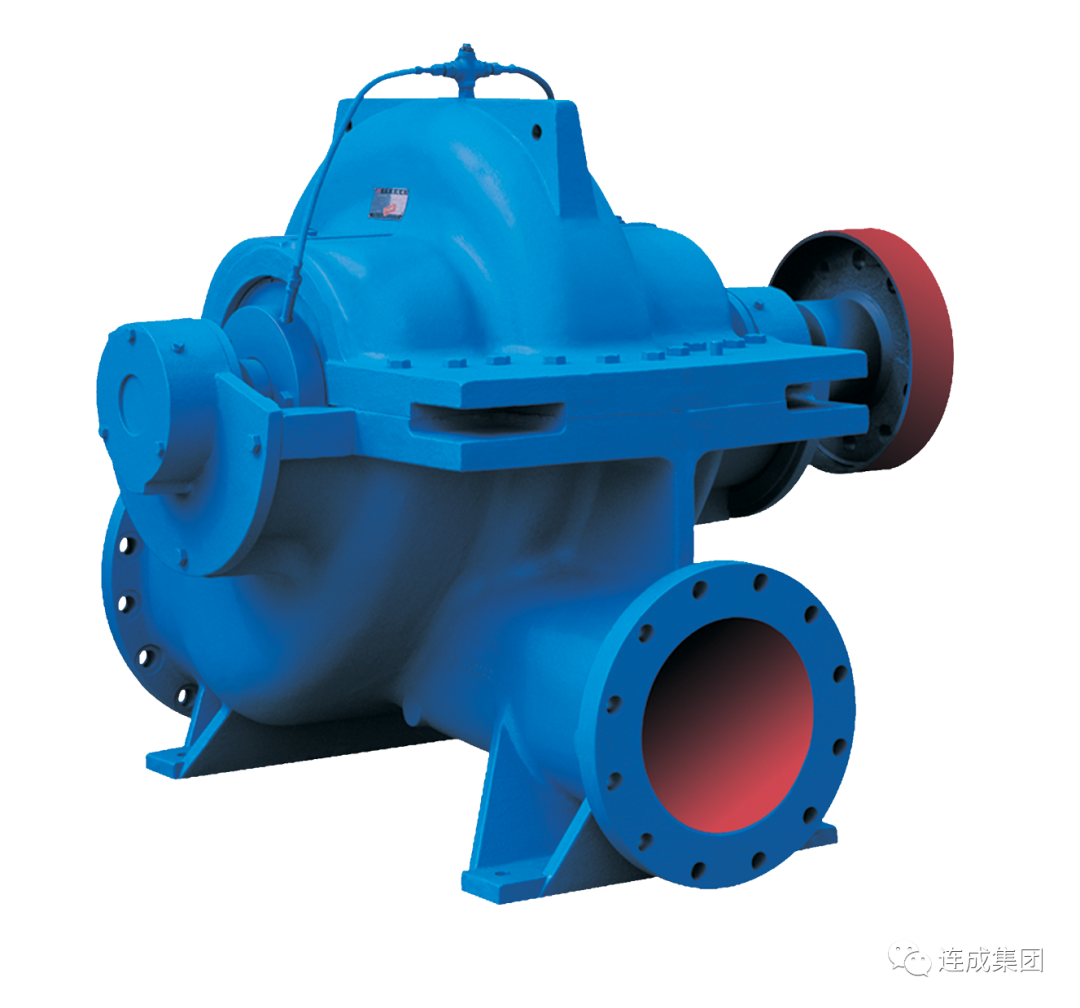

High-quality prerequisites must have high-quality technical personnel. The group company attaches great importance to the construction of the Suzhou stock technical team and actively deploys elite troops to enhance the technical strength of the Taicang factory in the future. The Group Research Institute and Taicang Technology Department cooperated to design and develop the SLOWN high-efficiency double-suction pump. Most of the products developed meet the national standard efficiency, and some products are much higher than the national standard, greatly enhancing the company’s technical competitiveness in the industry.

High-speed and high-quality development of an enterprise requires a combat team, because of the epidemic we have experienced challenges. “We are always ready” to climb to a higher goal, Shanghai Liancheng Group Suzhou Co., Ltd. will surely develop into the industry’s Optimus Prime, we will certainly experience leapfrog development, and truly become a model enterprise in the industry.